News

S500-4 evaporator put into operation in the Czech Republic

A&P News / 29.06.2023

At the end of June, Arnold & Partner AG was able to hand over another evaporation plant in the Ostrava region to the operator. The plant will process fermentation residues, which originate from the utilization of organic industrial waste, into high-quality fertilizer. With a water evaporation of 1800l/h, about 17500 tons of digestate can be processed annually.

Arnold evoporators installed in Hungary

A&P News / 08.09.2021

In Hungary, two Arnold evaporators, each with 7,000 litres of water evaporation per hour, have gone into operation at the largest bioethanol plant in Europe. Here, the digestate from the biogas plant is concentrated in the Arnold evaporator and then dried and pelletised.

WORLDWIDE NOVELTY: "ZERO LIQUID DISCHARGE" SYSTEM

A&P News / 27.11.2020

Oliver Arnold of CEO of Arnold & Partner AG introduces the company's "zero liquid discharge" system, creating pellets from agricultural waste.

Certification "Specialist company WHG"

A&P News / 10.08.2020

We are pleased to inform you that Arnold & Partner AG has been appointed by TÜV SÜD Industrie Service GmbH Germany as

Specialist company according to WHG

is certified according to § 62(1) AwSV. The certificate was handed over to us on 30.07.2020 and is valid for two years.

Assembly of the evaporator in the district of Cloppenburg (Germany)

A&P News / 14.04.2020

At the beginning of April 2020, the assembly of the main components of the latest evaporator took place in the district of Cloppenburg (Germany). The highly efficient evaporator has a heat demand of 800 kW and will predominantly process slaughterhouse waste from the on-site biogas plant.

Large meat producer relies on Arnold evaporator

A&P News / 23.03.2019

In the district of Cloppenburg, the highly efficient 4-stage evaporation plant with 800kW is to go into operation this winter. The Arnold evaporator will process 3600 l/h of slaughter waste from the biogas plant and evaporate more than 2700 l/h of water. The concentrate will be dried to a powder in the subsequent drying plant, then pelletised and marketed as a valuable fertilizer.

Vacuum evaporator sold in Bavaria

A&P News / 02.02.2019

Arnold & Partner AG sells another evaporation plant for digestate treatment in the Munich area. The plant evaporates 1,200 litres of water per hour, thus reducing the annual amount of liquid digestate by more than 10,000 m3. The plant is scheduled to go into operation in the summer of 2019.

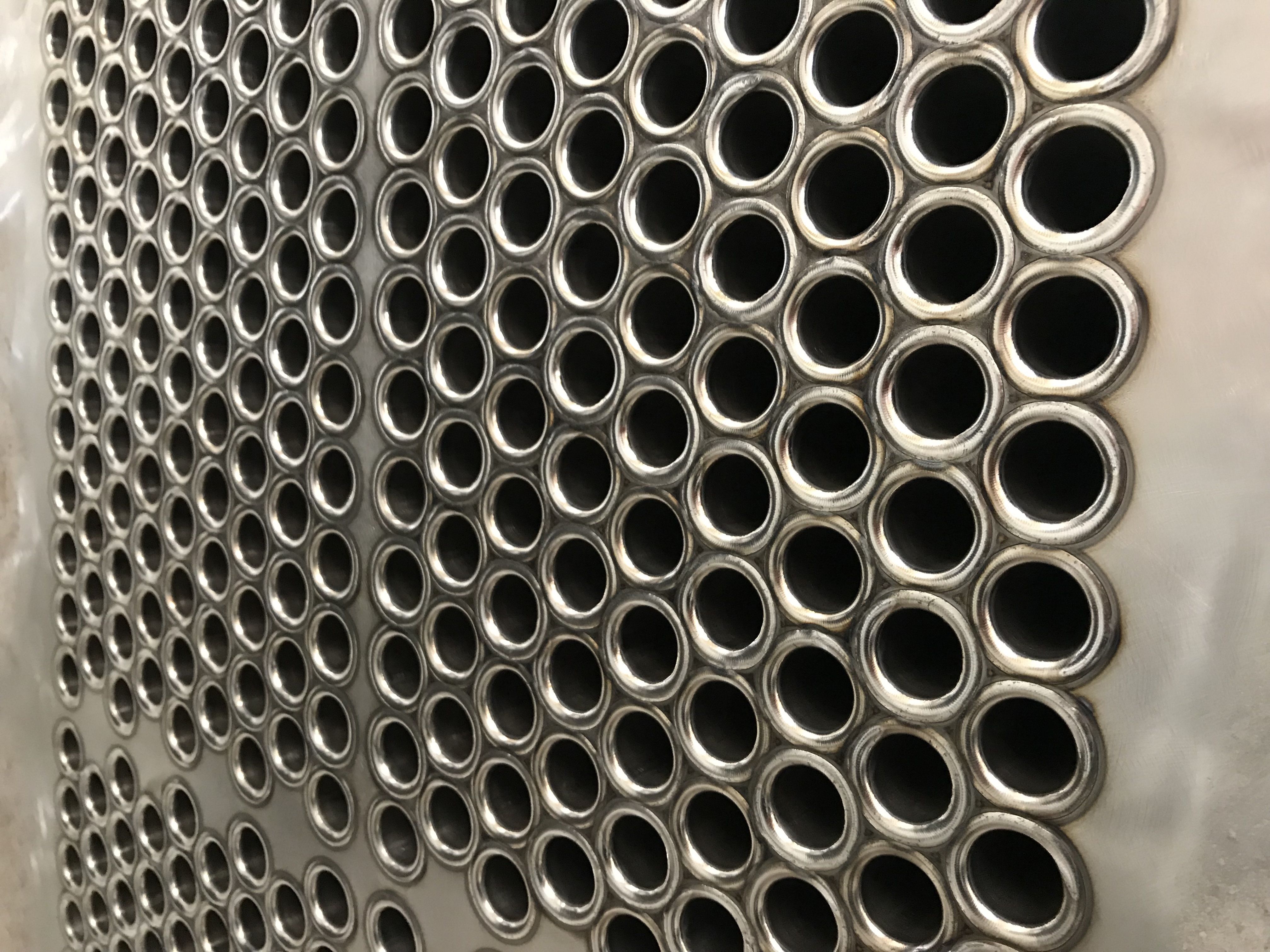

Heat exchangers Made in Switzerland

A&P News / 09.12.2018

The special Arnold shell-and-tube heat exchanger for vacuum evaporators granulates maintenance-free operation - developed, designed and produced in Switzerland.

The technology enables a high concentration of waste water (fermentation residues) with a maintenance-free operation of the heat exchanger - this is unique!

Further evaporation plant for digestate treatment sold in the Lower Saxony area

A&P News / 02.10.2018

Arnold & Partner AG sells another evaporation plant for digestate treatment in Lower Saxony. The plant evaporates 2,500 litres of water per hour, thus reducing the annual amount of liquid digestate by more than 20,000 m3. The plant is scheduled to go into operation at the beginning of 2019.

Arnold & Partner AG moves into the former Grundfos AG building in Schachen (LU)

A&P News / 01.07.2018

Arnold & Partner AG moves into the former building of Grundfos. In order to meet the high demand for evaporation plants and the growing mixer business, it was necessary to move to a larger building. The relocation of employees and the entire infrastructure was successfully completed in July.

Successful commissioning of the Gfellerhof biogas plant of the City of Zurich

A&P News / 01.04.2018

The biogas plant of Arnold & Partner AG on the Gfellerhof was successfully put into operation in the new year. The biocertified farm of the city of Zurich is of central importance for the management of agricultural land in the east of the city. The leaseholder family is engaged in dairy farming, arable farming and fruit growing. They are also actively involved in Grün Stadt Zürich's "Farm School" project.